Cable Mapping & Testing Products

Mapping and verification of External plant network records (mapping cables and pair records against telephone services). Also close-out testing and compliance to field processes.TM150 R&M 10-pair Line Card

Part No. 900 2002 150

Line Card for R&M 10 pair connectors

A$400.00(excluding GST)

Low in stock

TM150 R&M 16 pair Line Card

Part No. 900 2003 150

Line Card for R&M 16 pair connectors

A$640.00(excluding GST)

Low in stock

TM150 R&M 20 pair Line Card

Part No. 900 2004 150

Line Card for R&M 20 pair connectors

A$800.00(excluding GST)

Low in stock

TM150 Quante 10 pair Line Card

Part No. 900 2005 150

Line card for Quante 10 pair termination connectors

A$400.00(excluding GST)

In stock

TM150 Quante 20 pair Line Card

Part No. 900 2006 150

Line cards for Quante 20 pair termination connectors

A$800.00(excluding GST)

In stock

TU150 Controller Kit

Part No. 900 2012 150

The controller kit consists of 2 x Controllers with Batteries, 2 x Long USB cables, 2 x Long Link Cables, 2 x Earth Leads, 1 x Carry Case

- TX150 Installer (Installer) application/octet-stream 10.9 mB

- TX150 Installer

A$1000.00(excluding GST)

In stock

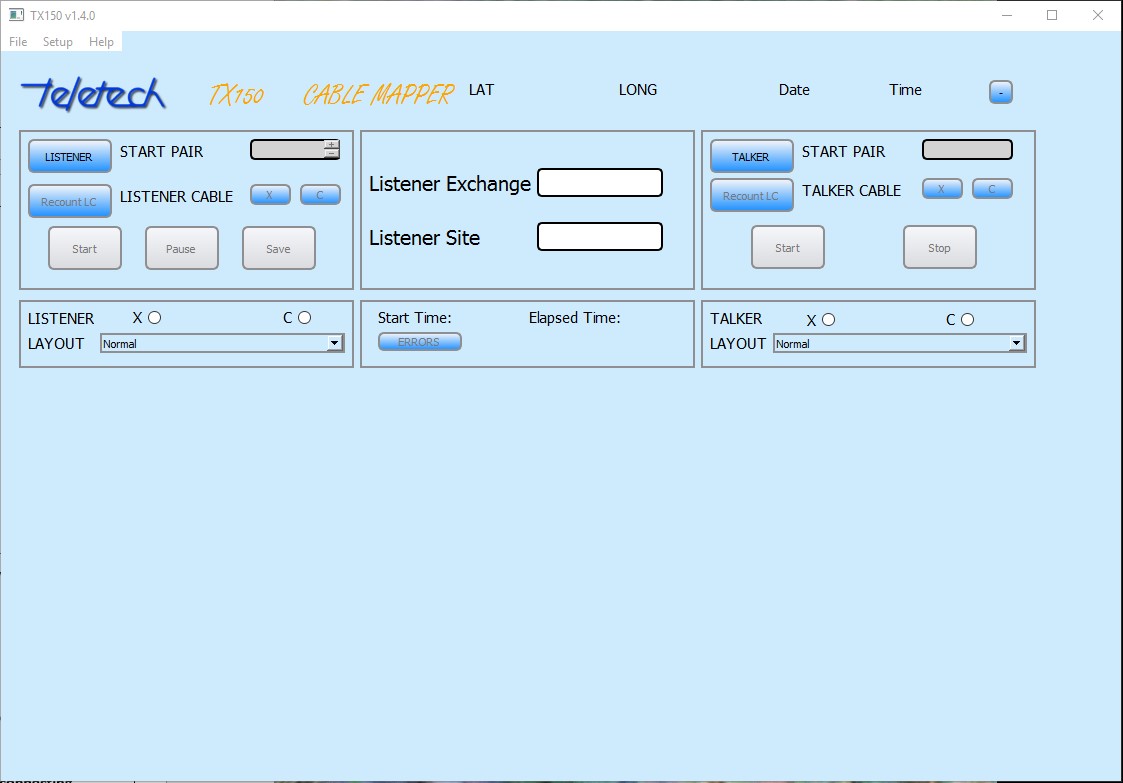

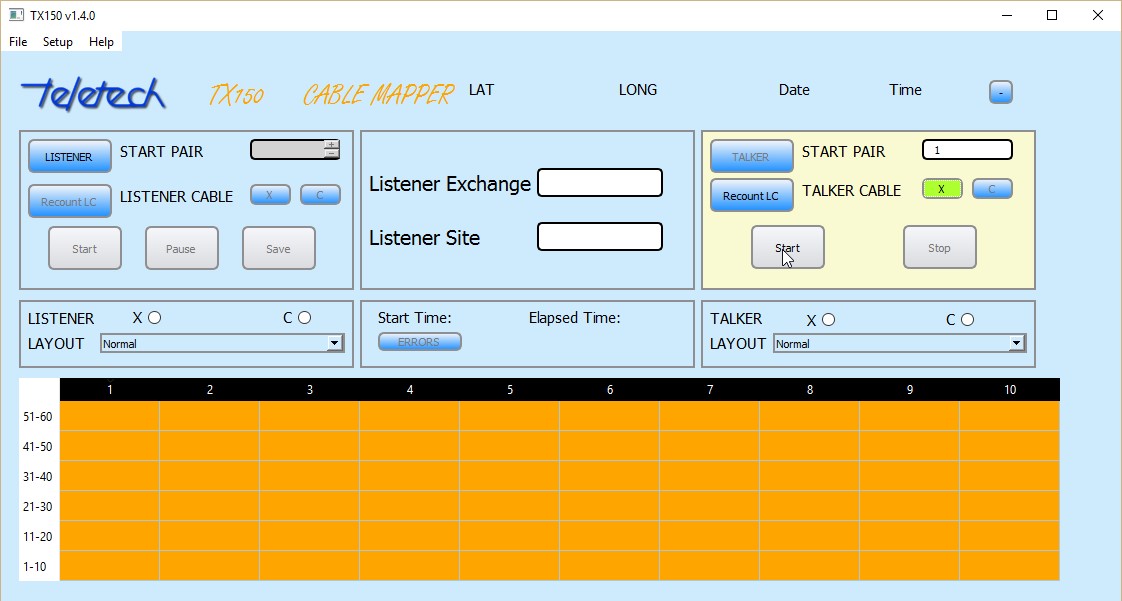

TX150

The TX150 Kit is made up of a TU150 controller kit and TM150 Line Cards. The customer can decide what Line Cards will suit their testing and buy them to build up a kit of TX150.

The TX150 is designed to check cable terminations between each end of a multi-pair cable. Line Cards are plugged into the terminating blocks at each end. At each end the Line Cards are joined together with Link Cables and the first Line Card at each end is connected to a Controller (TU150). The Controller and Line Cards are t each end powered by a separate battery. One end is designated the Talker and the other end is designated the Listener. The Talker end sends signals on each pair of the cable and the Listener end identifies these signals. All signals are transmitted simultaneously so identification of pairs is very quick (less than 10 seconds).

- TX150 Line Card Updater (Installer) application/x-msdownload 0.3 mB

- LC Updater

- TX150 Updater Instructions (Installer) application/pdf 0.4 mB

- LC Firmware install instructions

- TX150 Brochure (Brochure) application/pdf 1.2 mB

- Brochure for TX150 Kit

- TX150 Instruction Manual (Instruction Manual) application/pdf 2.8 mB

- The instruction manual on how to use the TX150.

- TX150 Installer (Installer) application/x-msdownload 40.8 mB

- The installer for TX150v1.5.0.

- TX150 Installer (with updated libraries) (Installer) application/x-msdownload 42.5 mB

- The installer for TX150v1.5.0 with updated libraries.

- TX150 Installer (Installer) application/octet-stream 10.9 mB

- TX150 Installer

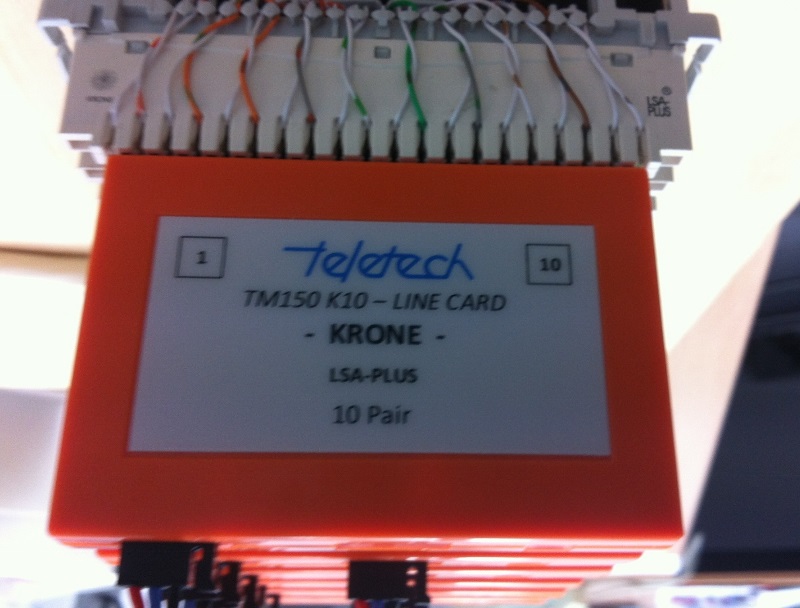

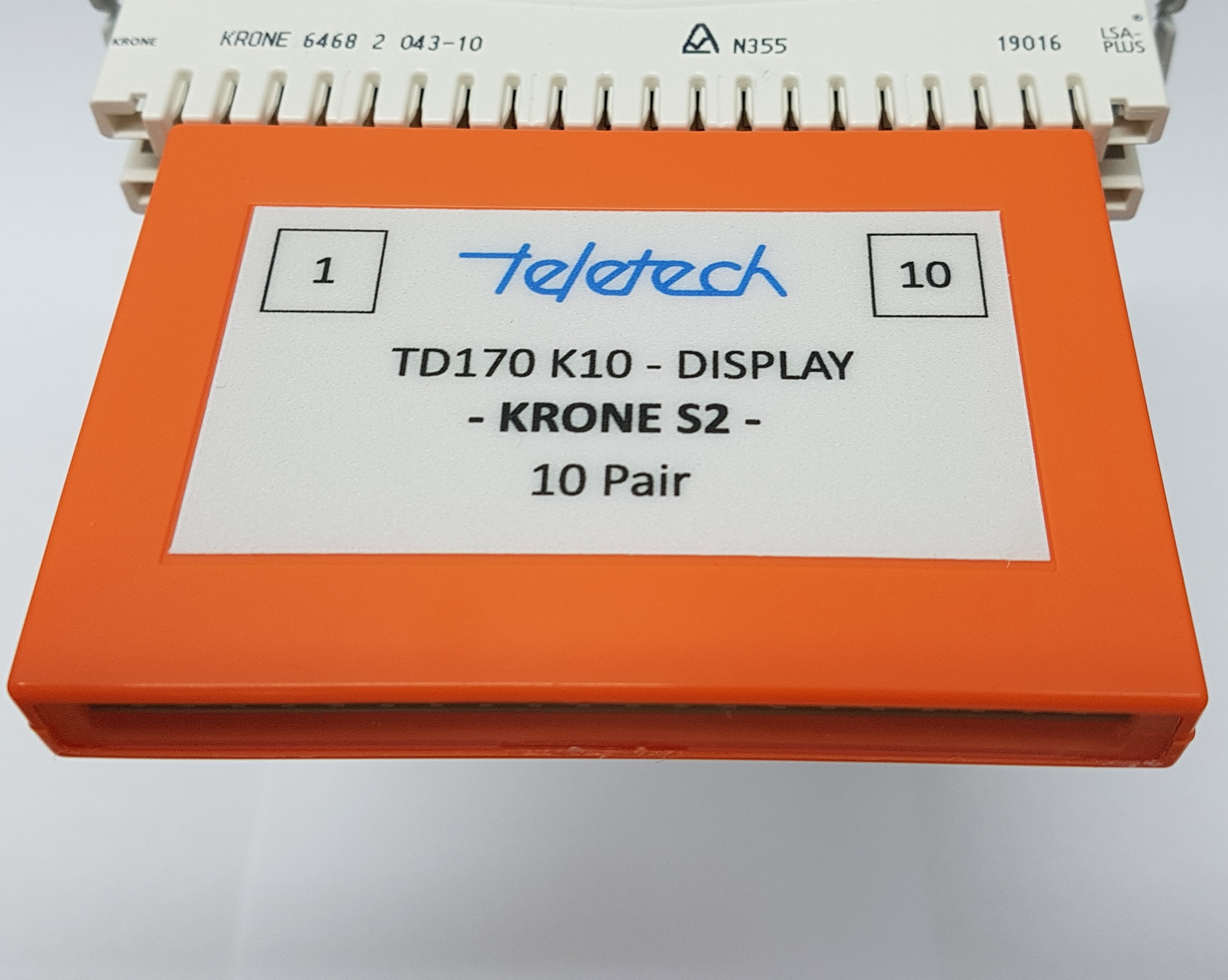

TM150 Krone 10 pair Line Card

Part No. 900 2015 150

Krone Line Card

A$400.00(excluding GST)

In stock

TM150 Krone HD180 10 pair Line Card

Part No. 900 2016 150

Connector for Krone HD180 blocks

A$400.00(excluding GST)

In stock

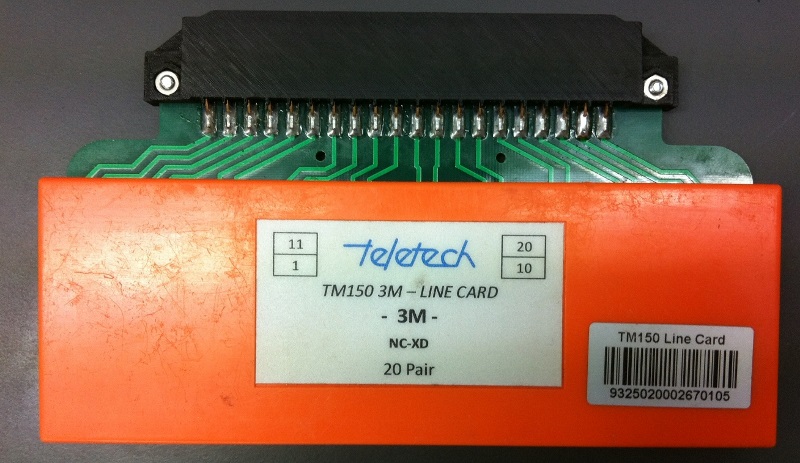

TM150 3M 20 Pair Line Card

Part No. 900 2017 150

3M 20 Pair line Card for use with Madision

A$880.00(excluding GST)

Low in stock

Wizard170 - TX170 kit

Part No. 900 2301 170

The Wizard170 is a test instrument to check cable terminations to Krone blocks. It will find open circuits, short circuits, transposed pairs, split pairs and polarity reversals.

The Wizard170 will test cable terminations between two 10-pair Krone blocks in less than a minute.

The wizard170 operates from a single 5V Power Bank. The Sender Unit cycles through each pair one at a time from pair 1 to pair 10 and then repeats. The Display Unit illuminates an LED corresponding to the pair being checked, Red for the "a" wire and Blue for the "b" wire. Each LED should light in sequence from pair 1a to pair 10b. If an LED lights out of sequence then there is a wiring error. The slide switch on the Sender Unit can be pushed to the right to slow the test down to make it easier to identify errors.

- Wizard170 Brochure (Brochure) application/pdf 0.5 mB

- Wizard170 information

- Wizard170 Operating Instructions (Instruction Manual) application/pdf 1.0 mB

- Operating Instructions for the Wizard170.

A$540.00(excluding GST)

In stock

Central Responder Unit Test Heads

Part No. 900 1790 000

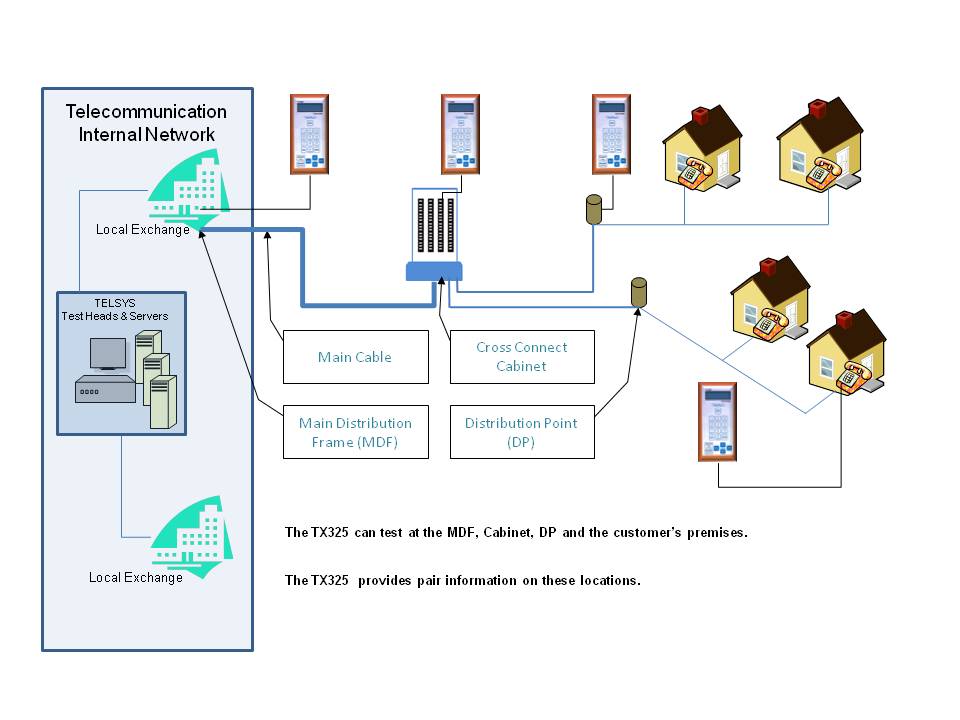

The CRU is at the heart of the TELSYS system. The CRU consists of tests heads and computer servers.

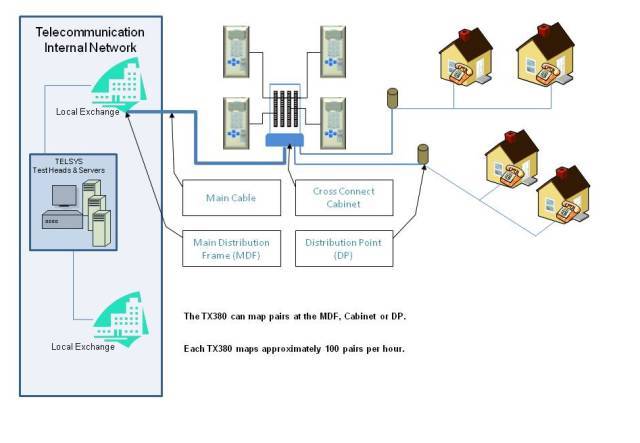

TX380 Kit

Part No. 900 1941 380

Teletech’s TX380 is a hand held test instrument designed to map, test and verify telecommunication cable records. It can be used at exchange MDFs, SDF or cross-connect cabinets. The TX380 operate with the TELSYS system.

The system of TELSYS, CRU and TX380s is designed to enable ‘full’ mapping of the cable network.

The TX380s system is able to map:

• Exchange side pairs;

• Customer side pairs;

• MDF pairs.

The TX380s system is able to map:

• Exchange side pairs;

• Customer side pairs;

• MDF pairs.

Benefits

• Find spare capacity in the network;

• Identify broadband capable pairs and network broadband capability;

• Increase the cable plant record accuracy leading to reduced maintenance costs; and

• Quicker, easier and more accurate mapping than traditional methods.

The TX380 is a component test instrument. The TX380 has features such as:

• Light weight;

• Rechargeable (4 x AA Batteries);

• Input fields for network descriptions;

• User friendly interface;

• Alpha numeric keypad;

• Pair tracing function;

• Multi-meter function; and

• Quick testing.

• Find spare capacity in the network;

• Identify broadband capable pairs and network broadband capability;

• Increase the cable plant record accuracy leading to reduced maintenance costs; and

• Quicker, easier and more accurate mapping than traditional methods.

The TX380 is a component test instrument. The TX380 has features such as:

• Light weight;

• Rechargeable (4 x AA Batteries);

• Input fields for network descriptions;

• User friendly interface;

• Alpha numeric keypad;

• Pair tracing function;

• Multi-meter function; and

• Quick testing.

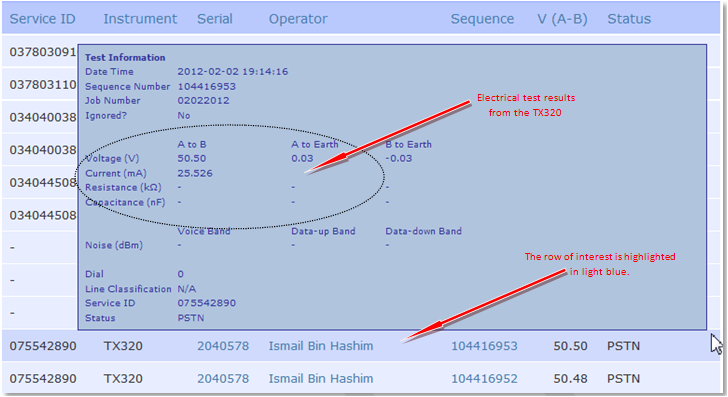

As well as mapping the cable pairs, the TX380 performs accurate testing of many cable parameters. The results of the tests are stored in TELSYS for future analysis. These tests include:

• DC and AC Voltage;

• Line Current;

• Insulation Resistance;

• Capacitance;

• Capacitance Balance; and

• VF and Broadband Noise

The TX380 can perform noise tests to check the suitability of a pair for Broadband services. It is possible to estimate the Broadband attenuation and Signal to Noise Ratio and calculate the ADSL upload and download speeds.

• DC and AC Voltage;

• Line Current;

• Insulation Resistance;

• Capacitance;

• Capacitance Balance; and

• VF and Broadband Noise

The TX380 can perform noise tests to check the suitability of a pair for Broadband services. It is possible to estimate the Broadband attenuation and Signal to Noise Ratio and calculate the ADSL upload and download speeds.

- TX380 (Brochure) application/pdf 0.5 mB

A$5000.00(excluding GST)

Not in stock

TX325 Field Test Instrument

Part No. 900 1971 325

The TX325 is a product developed specifically for telecommunications companies to improve operational efficiency. It provides the functionality to upload test results into a database for permanent storage and retrieval. Telephone companies are fairly unique in having a large buried copper network serviced by a large mobile field workforce. The quality of the installation and service activity significantly impacts on the maintenance costs. The quality issues become more critical if/when external contractors are employed in the field workforce. The TX325 provides an opportunity for telephone companies to control the field quality and at the same time rationalise back office functions.

The TX325 provides:

• Simplify and automate plant record update;

• Back office cost reductions; and

• Uniformity to operational processes – trouble handling procedures.

Significant opportunities exist for improving a telecom company’s efficiency in operations – that is, the area that manages and maintains the external plant network (also known as the Customer Area Network CAN). Operations is where the business of installing and maintaining services happens. Operations areas typically generate little revenue but they consume a large proportion of expenses, in the order of 60% of the total budget.

• Simplify and automate plant record update;

• Back office cost reductions; and

• Uniformity to operational processes – trouble handling procedures.

Significant opportunities exist for improving a telecom company’s efficiency in operations – that is, the area that manages and maintains the external plant network (also known as the Customer Area Network CAN). Operations is where the business of installing and maintaining services happens. Operations areas typically generate little revenue but they consume a large proportion of expenses, in the order of 60% of the total budget.

The TX325 is a component test instrument. The TX325 has features such as:

• Light weight;

• Rechargeable (4 x AA Batteries);

• Input fields for network descriptions;

• User friendly interface;

• Alpha numeric keypad;

• Pair tracing function;

• Multi-meter function; and

• Quick testing.

• Light weight;

• Rechargeable (4 x AA Batteries);

• Input fields for network descriptions;

• User friendly interface;

• Alpha numeric keypad;

• Pair tracing function;

• Multi-meter function; and

• Quick testing.

The TX325 performs accurate testing of a comprehensive number of cable parameters. The results of the tests can be stored in TELSYS for future analysis. These tests include:• DC Voltage (A-B),(A-G) & (B-G)

• AC Voltage;

• Line Current (A-B);

• Insulation Resistance (A-B),(A-G) & (B-G);

• Capacitance (A-B),(A-G) & (B-G);

• Capacitance Balance; and

• VF and Broadband Noise.

• AC Voltage;

• Line Current (A-B);

• Insulation Resistance (A-B),(A-G) & (B-G);

• Capacitance (A-B),(A-G) & (B-G);

• Capacitance Balance; and

• VF and Broadband Noise.

- TX325 (Specification) application/pdf 0.4 mB

- Instrument Specifications

- TX325 (Brochure) application/pdf 0.9 mB

- TX325 Brochure

A$1810.00(excluding GST)

Not in stock

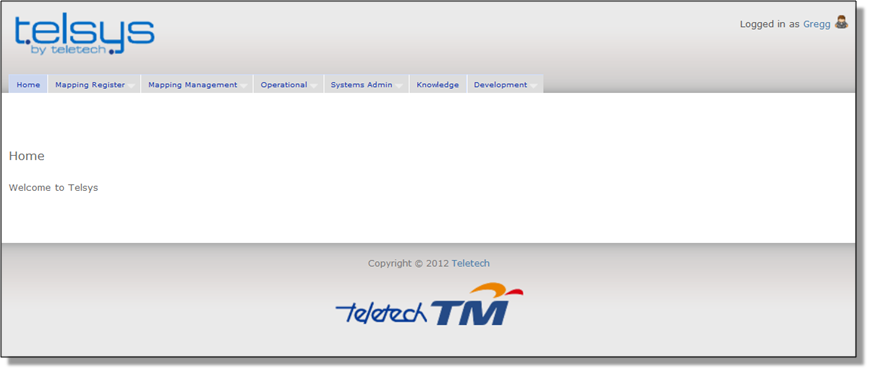

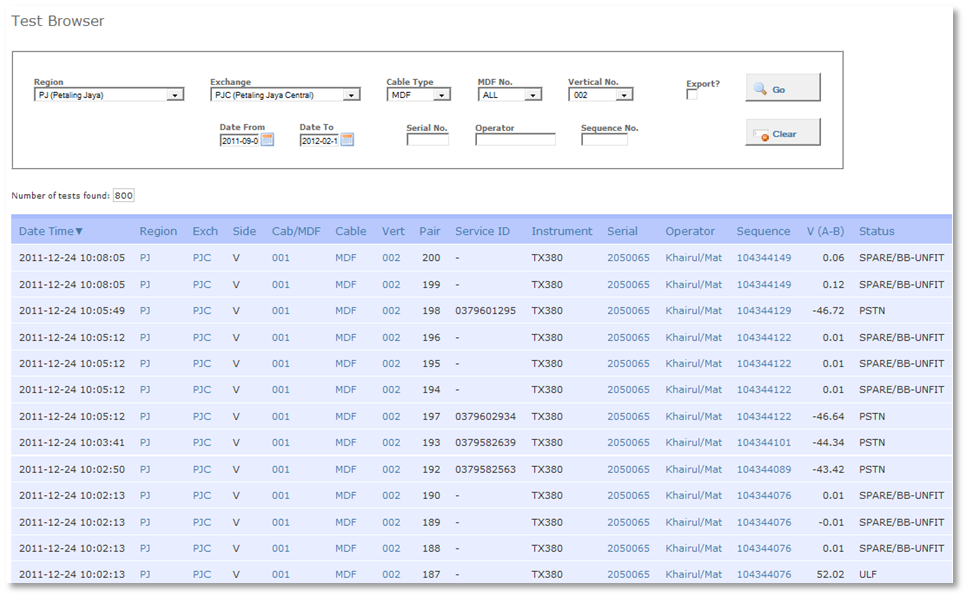

TELSYS Cable Mapping & Verification

TELSYS is a Teletech developed system that has multiple roles in a telecommunication company. It consists of various components but is primarily a centralised test system that operates with field test instruments. The system broadly provides functionality for:

• Mapping and verification of External plant network records (cable and pair records);

• Mapping and verification of Next Generation Network exchange cutovers;

• Automated update of cable records;

• Close-out testing and compliance to field processes; and

• Prequalification for Broadband (triple play services).

TELSYS is the reporting window of the various field instruments. The field instruments that interface and upload data and testing information are the TX380 and TX325/320B and TX320.

• Mapping and verification of External plant network records (cable and pair records);

• Mapping and verification of Next Generation Network exchange cutovers;

• Automated update of cable records;

• Close-out testing and compliance to field processes; and

• Prequalification for Broadband (triple play services).

TELSYS is the reporting window of the various field instruments. The field instruments that interface and upload data and testing information are the TX380 and TX325/320B and TX320.

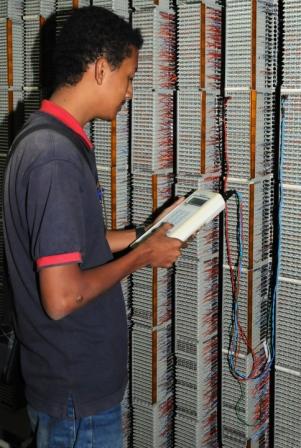

Pair Mapping & Verification (Cabinet or Main Distribution Frame (MDF))

Teletech has been particularly successful with external plant (Customer Area Network (CAN)) documentation projects. Plant documentation projects involve completely documenting the condition of the copper cable.

Accurate cable records have been shown to have significant impacts on the operational performance and costs of telecommunication companies. The areas that benefit from accurate records are:

• Technician dispatch (less time looking for the pair);

• Trouble resolution time (go direct to the pair, less time wasted looking);

• Related to customer satisfaction (less time off the air);

• Capital expenditure decision-making is better informed and expenditure focused on real areas of need;

• New network investment (upgrading from POTS to high-speed data and video services);

• Plant capacity management; and

• Change over to new OSS systems (pre-cleanse the cutover data).

TELSYS suits telecommunication providers wanting to update their copper cable records. The ROI for cable plant record verification can be very high. The plant documentation projects can be one-off activity, such as, introducing new networks or on-going up-keep of the plant records. Either way, the TELSYS system can deliver the return.

MDF Mapping & Verification

When commissioning new exchange equipment, TELSYS , TX380s and multiplexers can be used to map the MDF before and after cutover to both eliminate error and dramatically reduce the time taken to maintain the exchange records. The test results are uploaded for each pair at the exchange and can be automatically compared to the existing cable record system’s data. Each working telephone line can therefore be accounted for and their location verified before and after cut-over. This type of system is both quicker and more accurate than manual checking.

Case Studies

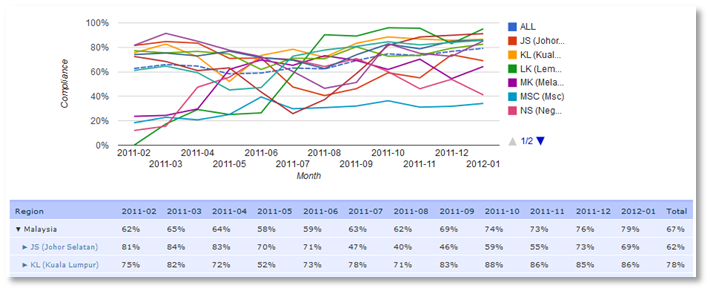

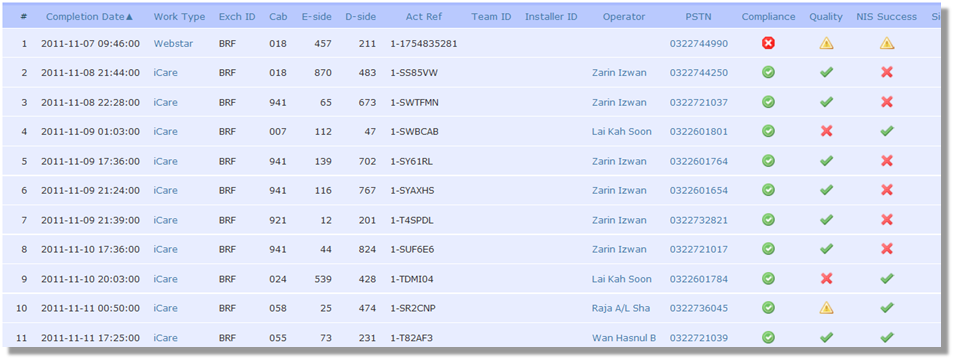

Reduce truck-rolls (rework on maintenance dispatches)A large telco was concerned that the trouble rate (dispatches per 1000 pairs) was too high. It was determined that part of the problem was too many additional re-reported faults dispatched to the field (re-rolls) creating unnecessary field technician dispatches and reduced customer service quality. Teletech worked with the telco to introduce a centralized test system (CRU), field test equipment and web-based management system that tracked and reported compliance to the required job close out processes. This enabled management to enforce the required testing processes and track improvements in the re-roll metrics.

The system also provides a detailed fault history on each fault dispatch. This proved invaluable and has become an integral part of the escalated fault technician’s tool kit for resolving difficult service issues.

Improved on-going Cable Record error rates

A major South East Asian telco recognised they had a problem with the accuracy of their cable records. The industry standard for the MDF or Exchange (E) side of the cross connect cabinet is approximately 1 to 5% error rate in the primary cable. The standard for the distribution (D) side (the cable from the cabinet to the customer) is approximately 5 to 10% error rate.

The telco was finding error rates of >30% in some areas. In conjunction with a plant documentation projects the introduction of TX325 instruments and associated centralised test system allowed the telco to automate the update of external plant records and significantly improve the accuracy. There were others bonuses, the telco also obtained information on the broadband quality of the installed or repaired services and used this for revenue generation purposes and the automation of the cable record changes allowed back-office cost savings.

Teletech has been particularly successful with external plant (Customer Area Network (CAN)) documentation projects. Plant documentation projects involve completely documenting the condition of the copper cable.

Accurate cable records have been shown to have significant impacts on the operational performance and costs of telecommunication companies. The areas that benefit from accurate records are:

• Technician dispatch (less time looking for the pair);

• Trouble resolution time (go direct to the pair, less time wasted looking);

• Related to customer satisfaction (less time off the air);

• Capital expenditure decision-making is better informed and expenditure focused on real areas of need;

• New network investment (upgrading from POTS to high-speed data and video services);

• Plant capacity management; and

• Change over to new OSS systems (pre-cleanse the cutover data).

TELSYS suits telecommunication providers wanting to update their copper cable records. The ROI for cable plant record verification can be very high. The plant documentation projects can be one-off activity, such as, introducing new networks or on-going up-keep of the plant records. Either way, the TELSYS system can deliver the return.

MDF Mapping & Verification

When commissioning new exchange equipment, TELSYS , TX380s and multiplexers can be used to map the MDF before and after cutover to both eliminate error and dramatically reduce the time taken to maintain the exchange records. The test results are uploaded for each pair at the exchange and can be automatically compared to the existing cable record system’s data. Each working telephone line can therefore be accounted for and their location verified before and after cut-over. This type of system is both quicker and more accurate than manual checking.

Case Studies

Reduce truck-rolls (rework on maintenance dispatches)A large telco was concerned that the trouble rate (dispatches per 1000 pairs) was too high. It was determined that part of the problem was too many additional re-reported faults dispatched to the field (re-rolls) creating unnecessary field technician dispatches and reduced customer service quality. Teletech worked with the telco to introduce a centralized test system (CRU), field test equipment and web-based management system that tracked and reported compliance to the required job close out processes. This enabled management to enforce the required testing processes and track improvements in the re-roll metrics.

The system also provides a detailed fault history on each fault dispatch. This proved invaluable and has become an integral part of the escalated fault technician’s tool kit for resolving difficult service issues.

Improved on-going Cable Record error rates

A major South East Asian telco recognised they had a problem with the accuracy of their cable records. The industry standard for the MDF or Exchange (E) side of the cross connect cabinet is approximately 1 to 5% error rate in the primary cable. The standard for the distribution (D) side (the cable from the cabinet to the customer) is approximately 5 to 10% error rate.

The telco was finding error rates of >30% in some areas. In conjunction with a plant documentation projects the introduction of TX325 instruments and associated centralised test system allowed the telco to automate the update of external plant records and significantly improve the accuracy. There were others bonuses, the telco also obtained information on the broadband quality of the installed or repaired services and used this for revenue generation purposes and the automation of the cable record changes allowed back-office cost savings.

Advantages of the TELSYS system

TELSYS has some distinct advantages over traditional mapping methodologies.

Compared to manual mapping the system has proven to be more accurate and quicker. Using a manual methodology involves clipping onto each pair, dialing a CLI number and writing down a phone number on a piece of paper. This very laborious ‘Tick and Flick’ process is very prone to translation and transcription errors. As an operator become more fatigued or bored the risk they miss hear the phone number, write down a transposed number increase. If the paper records need to be converted to into an electronic record, more error creeps either from miss-keying and/or miss-reading the handwritten records. Because TELSYS collects the phone numbers automatically from the multiplexer connectors none of these root error causes are present.

The accuracy of TELSYS mapping is further enhanced by using a systemic approach to auditing of the mapping effort. Management can know with mathematical certainty the mapping has been accurately performed.

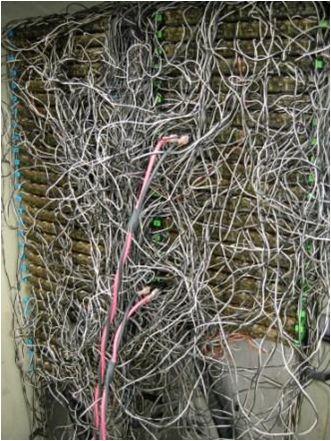

Another disadvantage of manual collection is that it is quite slow. The speed of mapping is limited by the speed of each operator. This can be solved in part be employing a large workforce of operators. However, at cabinets and exchange MDFs there is a limited amount of space available. In contract, a very small team of operators using TX380s and multiplexers can map large numbers of pairs simultaneously. Multiplexers can be connected to hundreds of pairs at a cabinet or MDF. If desired it is possible to connect all pairs on a side of a cabinet to Multiplexers. With this configuration the TX380 testing and mapping of the cabinet would take under two hours.

Manually collecting cable pair information does not practically allow the collection of information on the cables other than the existence or non-existence of a phone service. It may be possible to use test instruments such as multi-meters to test pairs, however, besides slowing the mapping process it also is very limited in the information able to be collected. Using Tx380s on the other hand automates the collection of test information about all pairs. In particular, the broadband capabilities of the pairs are assessed. The test data is stored and reported. Allowing a telco to have the dual benefits of accurate records and identified broadband capacity.

There are some other non-manual cable/pair mapping systems beside TELSYS. These systems employ a different methodology from TELSYS to collect their data. TELSYS was designed with access and transportability in mind. The result is that the field instrument (TX380) is very transportable and operates with rechargeable AA batteries. Most of the real processing power of the system is centrally located.

In contract, other mapping systems have bulky equipment requiring vans or large vehicles to transport. They also require separate power sources to operate. These are addition and possibly hidden costs that the use of TELSYS avoids. Easy of transportation also has another intended benefit, it makes for speeder mapping. An individual can comfortable carry enough TX380s and multiplexers to concurrently map a thousand pairs. The equivalent equipment used for other mapping systems would require several vans.

The TX380s and multiplexers are very easy and simple to operate. The cost is very low to train operators to be competent in the use of the equipment.

The level of training and equipment is in some respects dependent on the outcome the telecommunication company is seeking. If the cabinets require rehabilitation this will require more skilful operators with extra tools, for example to remove old jumper wire and punch down wires. Circumstances vary between telcos and this level of work may not be required.

TELSYS has some distinct advantages over traditional mapping methodologies.

Compared to manual mapping the system has proven to be more accurate and quicker. Using a manual methodology involves clipping onto each pair, dialing a CLI number and writing down a phone number on a piece of paper. This very laborious ‘Tick and Flick’ process is very prone to translation and transcription errors. As an operator become more fatigued or bored the risk they miss hear the phone number, write down a transposed number increase. If the paper records need to be converted to into an electronic record, more error creeps either from miss-keying and/or miss-reading the handwritten records. Because TELSYS collects the phone numbers automatically from the multiplexer connectors none of these root error causes are present.

The accuracy of TELSYS mapping is further enhanced by using a systemic approach to auditing of the mapping effort. Management can know with mathematical certainty the mapping has been accurately performed.

Another disadvantage of manual collection is that it is quite slow. The speed of mapping is limited by the speed of each operator. This can be solved in part be employing a large workforce of operators. However, at cabinets and exchange MDFs there is a limited amount of space available. In contract, a very small team of operators using TX380s and multiplexers can map large numbers of pairs simultaneously. Multiplexers can be connected to hundreds of pairs at a cabinet or MDF. If desired it is possible to connect all pairs on a side of a cabinet to Multiplexers. With this configuration the TX380 testing and mapping of the cabinet would take under two hours.

Manually collecting cable pair information does not practically allow the collection of information on the cables other than the existence or non-existence of a phone service. It may be possible to use test instruments such as multi-meters to test pairs, however, besides slowing the mapping process it also is very limited in the information able to be collected. Using Tx380s on the other hand automates the collection of test information about all pairs. In particular, the broadband capabilities of the pairs are assessed. The test data is stored and reported. Allowing a telco to have the dual benefits of accurate records and identified broadband capacity.

There are some other non-manual cable/pair mapping systems beside TELSYS. These systems employ a different methodology from TELSYS to collect their data. TELSYS was designed with access and transportability in mind. The result is that the field instrument (TX380) is very transportable and operates with rechargeable AA batteries. Most of the real processing power of the system is centrally located.

In contract, other mapping systems have bulky equipment requiring vans or large vehicles to transport. They also require separate power sources to operate. These are addition and possibly hidden costs that the use of TELSYS avoids. Easy of transportation also has another intended benefit, it makes for speeder mapping. An individual can comfortable carry enough TX380s and multiplexers to concurrently map a thousand pairs. The equivalent equipment used for other mapping systems would require several vans.

The TX380s and multiplexers are very easy and simple to operate. The cost is very low to train operators to be competent in the use of the equipment.

The level of training and equipment is in some respects dependent on the outcome the telecommunication company is seeking. If the cabinets require rehabilitation this will require more skilful operators with extra tools, for example to remove old jumper wire and punch down wires. Circumstances vary between telcos and this level of work may not be required.

TELSYS consists of:

• Field instruments (TX380s);

• Connector shoes;

• Central Responder Unit (CRU) test heads;

• Central database and webserver.

This system is able to map:

• Main Distribution Frame (MDF)

• Vertical side

• Horizontal side

• DSL Link In-Out

• Cabinets

• Exchange side

• Customer side

• DSL Link In-Out

• Sub-Distribution Frame (SDF) and/or DPs.

• Field instruments (TX380s);

• Connector shoes;

• Central Responder Unit (CRU) test heads;

• Central database and webserver.

This system is able to map:

• Main Distribution Frame (MDF)

• Vertical side

• Horizontal side

• DSL Link In-Out

• Cabinets

• Exchange side

• Customer side

• DSL Link In-Out

• Sub-Distribution Frame (SDF) and/or DPs.

- TELSYS (Brochure) application/pdf 1.0 mB

- Mapping

.jpg)

.jpg)